How to Choose the Right Thickness for Cut-to-Size Acrylic Sheets

Selecting the correct thickness for cut-to-size acrylic sheets is a crucial decision that significantly affects the performance, durability, and aesthetic appeal of your project. In this guide, we will explore the key factors to consider and offer insights to help you make a well-informed choice.

Understanding Acrylic Sheet Thickness

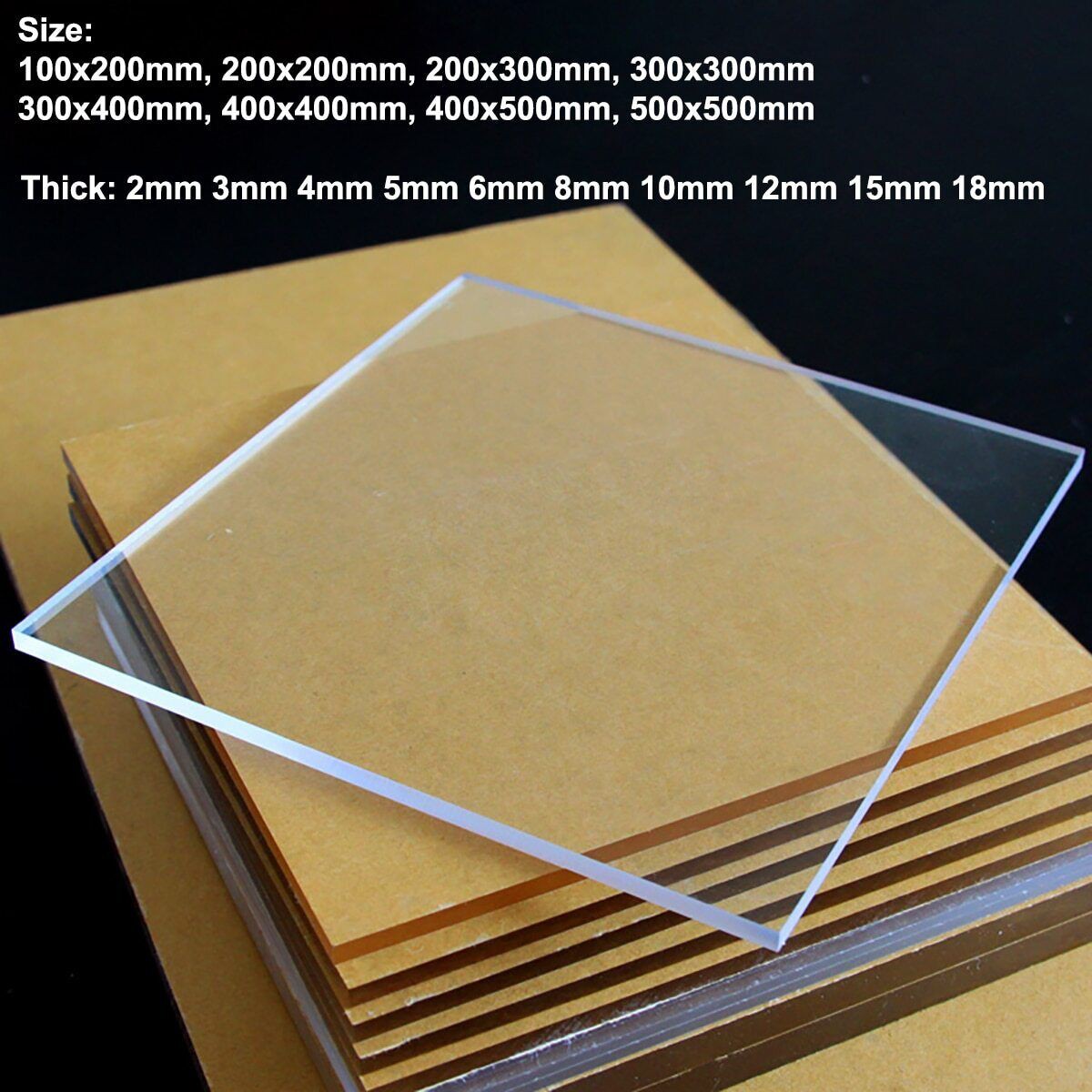

Acrylic sheet thickness is typically measured in inches or millimeters. Standard thickness options for cut-to-size sheets range from as thin as 1/16″ to 1/4″ or even thicker, depending on the specific requirements of your application.

Plexiglass Sheet Thickness Options

Plexiglass, a common term for acrylic, is available in a variety of thicknesses to accommodate different needs:

- Thin Sheets (0.080″ – 0.125″ / 2.0mm – 3.2mm): Ideal for lightweight applications such as picture frames, protective covers for artwork, and craft projects.

- Medium Sheets (0.1875″ – 0.250″ / 4.8mm – 6.4mm): Suitable for general-purpose uses, including signage, display cases, shelving, and protective barriers. These mid-range thicknesses offer a strong balance between durability and affordability.

- Thick Sheets (0.3071″ – 0.3780″ / 7.8mm – 9.6mm): Best for projects requiring greater structural integrity and impact resistance, such as windows, partitions, aquariums, and outdoor protective barriers.

For specialized applications, even thicker sheets (up to 0.500″ / 12.7mm or more) are available. These provide superior durability, strength, and insulation, often used in high-impact environments or structural installations.

Factors to Consider When Choosing Acrylic Sheet Thickness

1. Purpose and Application

The intended use of your project is a primary determinant of the appropriate acrylic thickness. For lightweight applications such as framing or displays, thinner sheets like 1/16″ or 1/8″ may be sufficient. However, for high-impact or structural applications like protective barriers or aquariums, thicker sheets (1/4″ or greater) are necessary to ensure strength and stability.

2. Durability and Strength

Thicker acrylic sheets provide enhanced durability, making them more resistant to impacts, bending, and external forces. For projects exposed to heavy use, high traffic, or outdoor conditions, opting for a thicker sheet will offer better long-term performance and reliability.

3. Weight and Handling

Acrylic sheets become heavier as the thickness increases, which can impact ease of handling and installation. If portability and ease of installation are critical for your project, consider thinner sheets to minimize weight without compromising functionality.

4. Aesthetics and Visual Clarity

The visual clarity and optical quality of acrylic can vary with thickness. Thinner sheets tend to offer superior transparency and are ideal for applications where clear visibility and a sleek look are important. Thicker sheets, while potentially less optically clear, can create a more substantial and bold visual presence, adding a sense of strength and solidity to the design.

5. Cost Considerations

The price of acrylic sheets increases with thickness due to the additional material required. When budgeting, weigh the need for thicker sheets against the project's functional demands. In many cases, a thinner sheet can meet the requirements at a lower cost, without compromising the overall effectiveness.

Choosing the right thickness for cut-to-size acrylic sheets is essential to ensuring both the success and longevity of your project. By evaluating factors such as the purpose, durability, weight, visual clarity, and cost, you can make a strategic decision that best fits your specific needs. Always assess the unique demands of your application, and when in doubt, consult with professionals to ensure optimal results.